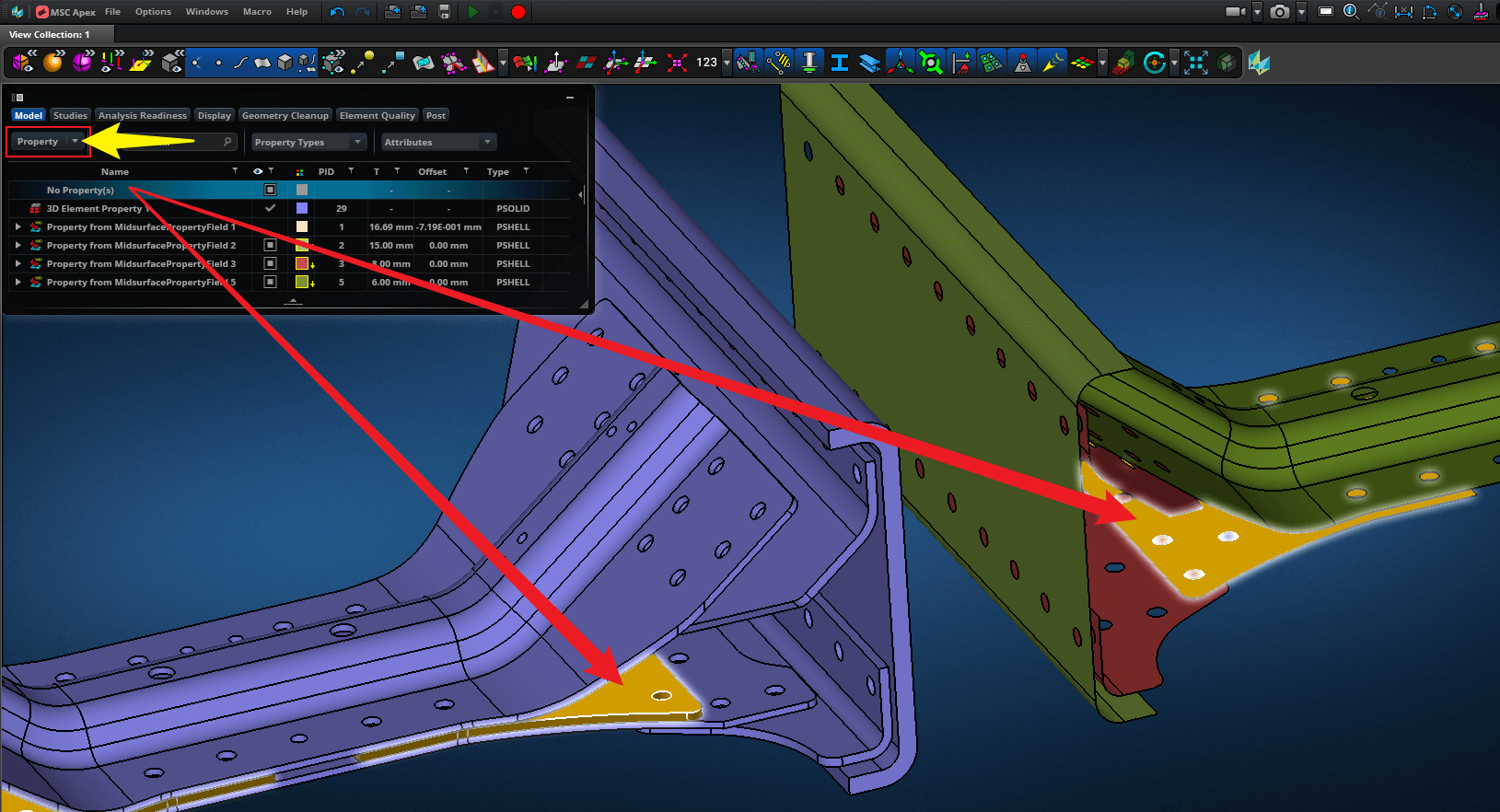

We are thrilled to announce the latest release of our flagship product, MSC Apex, now available in the Software Download Center. Our vision of MSC Apex is an easy-to-use, modern direct modelling and meshing solution for structural simulation and generative design. In our most recent releases, we’ve focused on boosting coverage for MSC Nastran to include linear, dynamics, nonlinear, and topology optimization workflows. Now all MSC Apex users will benefit from the significant investments we’ve made in both MSC Apex and MSC Nastran’s performance and user productivity. What’s new in MSC Apex 2024: Meshing enhancements: MSC Apex continues to build on its strong capabilities for moving from CAD to Mesh with two new tools. First, a new routine allows you to refine the shell mesh to limit the number of generated triangular elements. You’ll also be able to inject preexisting nodes and elements into a new mesh for more control over features and connections. MSC Nastran solution sequences: Version 2024.1 adds more coverage for MSC Nastran case-control and solution sequences, with a focus on dynamics to include frequency, transient, shock, and random response for both pre- and post-processing. Comprehensive support for Linear Statics (101), Normal Modes (103), Linear Buckling (105), Direct and Modal Frequency Response (108, 111), and Direct and Modal Transient Response (109, 112) are included in this release. MSC Nastran SOL 400 coverage: Expanded support for SOL 400 enables chained analyses, load combinations, and thermal-structural simulations, along with the conversion of nonlinear solutions ( SOLs106,129,153,159) to MSC Nastran’s comprehensive nonlinear tool, SOL 400. Enhanced user diagnostics for contact, convergence, and visualization are now available via scripting APIs. Compute and cloud connectivity: You’ll now have direct, on-demand access from MSC Apex to cloud compute resources for running large, complex MSC Nastran jobs, including seamless job submission, monitoring, and results retrieval to your desktop. Cloud compute resources are available via Nexus, Hexagon’s open digital reality platform. A free trial and flexible pricing models are available. Automation and customization: Enhanced user-defined graphics now allow seamless incorporation of a wide array of objects into the MSC Apex graphics window, including models for post-processing, charts, glyphs, and annotations. Significantly improve custom visualization for post-processing results without creating new windows. Database improvements: A new repair tool for same-version databases and a recovery file naming process provide a consistent, reliable database experience. Upgraded tutorials and demo videos: A new set of demo and how-to integrated tutorial videos to allow you to set up static, normal modes, dynamic, and nonlinear analysis. Additional videos will be released in the coming weeks. Improved user experience with missions: Seamlessly switch between MSC Nastran and MSC Apex Generative Design using missions. We are confident that these updates will improve the way you build MSC Nastran models with MSC Apex. Recent releases of MSC Apex have added support for over a thousand MSC Nastran keywords. With this project nearing completion, we will return to a focus on usability and improving workflows as well as comprehensive support for MSC Nastran solutions. We value your feedback and look forward to hearing about your experiences with the new features. Thank you for your continued support and trust in MSC Apex to contribute to your business success. See the full list of enhancements and learn more on Simcompanion View video tutorials and documents for MSC Apex in the Documentation Center |