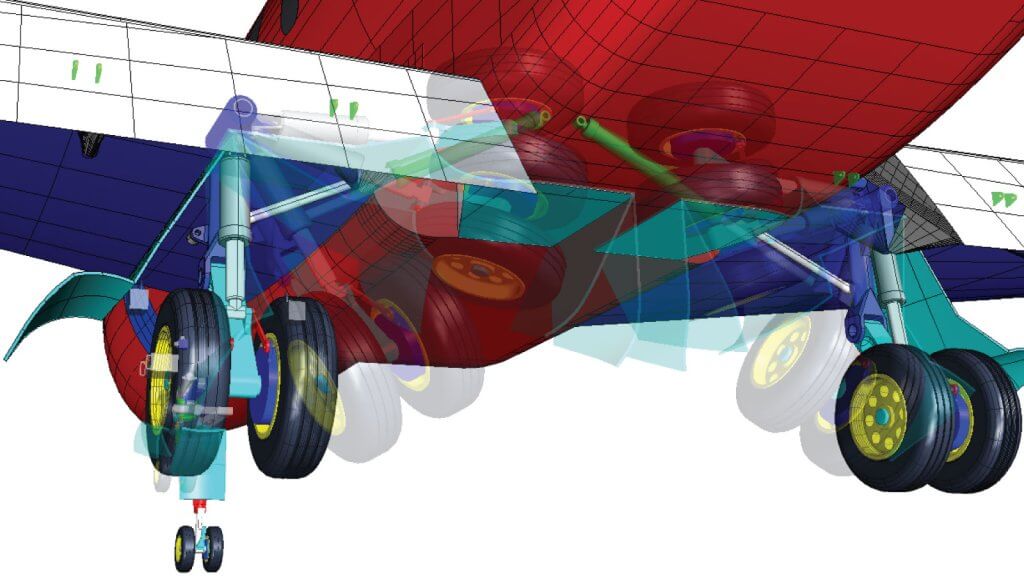

Structural analysis simulation software is a fundamental tool used in engineering to analyse and predict the behaviour of structures under various loads and conditions.

It enables engineers to simulate and evaluate factors such as stress, deformation and stability to ensure the structural integrity and safety of buildings, bridges and mechanical components.

By leveraging computational models and algorithms, structural analysis simulation software helps optimize designs, identify potential weaknesses and make informed decisions in industries ranging from civil engineering to aerospace and beyond.